Why Alignment Matters More Than Automation?

Too often, automation is treated like the ultimate destination. The shiny robots, the predictive maintenance alerts, the digital twins mapping every operation. These technologies promise efficiency, speed, and consistency. And they deliver. But factories that truly thrive are not just chasing the next tool or the newest system upgrade. They are building organisations where operations, planning, reporting, and leadership flow seamlessly into each other, creating a powerful competitive advantage.

When a factory is aligned, data is not just collected for compliance or archived in reports that sit unopened. It becomes an active language spoken across the shop floor, control rooms, and boardrooms. Operators see problems as they happen and fix them before they escalate. Planners do not spend their days firefighting but instead anticipate what is coming and prepare solutions in advance. Leaders do not just receive performance metrics but understand the context behind them, making strategic decisions rooted in the reality of daily operations.

Intelligent automation is not just about machines doing work—it's about reimagining how humans and technology collaborate to unlock new possibilities.

Alignment Transforms Manufacturing Culture

Alignment transforms the very culture of manufacturing. It dissolves silos between departments and teams. It bridges the gap between strategy and execution. It replaces confusion with clarity, delays with responsiveness, and fragmented decisions with unified direction. This clarity empowers every person in the organisation to act with confidence because they see where their work fits into the bigger picture and how it contributes to business goals.

Factories often invest in automation to reduce cycle times, improve consistency, and cut operational costs. But without alignment, these benefits remain localised and fail to create systemic improvement. Alignment ensures that process improvements are not just isolated to one cell or department but are scaled across the plant to create a truly agile manufacturing system.

The True Value of Data: From Collection to Action

In many factories, data collection has become extensive. Machines generate gigabytes of information daily. Sensors, IoT devices, and cloud platforms gather every reading imaginable. However, unless this data is accessible, understandable, and actionable by teams, it has little strategic value.

Alignment ensures data is not merely a digital exhaust but a fuel for decision-making. Operations teams use real-time data to prioritise and optimise their work. Planning teams integrate production realities with market demand seamlessly. Reporting teams create insights that go beyond graphs and numbers to reveal narratives about performance, bottlenecks, and opportunities. Leadership uses these insights to steer the organisation with confidence.

The Human Side of the Factory of the Future

The factory of the future is often imagined as a fully automated facility with minimal human intervention. But the reality is different. The most competitive factories are those where humans and machines work together in a connected, coordinated, and aligned way.

Imagine teams gathering around digital dashboards, analysing live data, reviewing production schedules, and solving problems collaboratively. Engineers adjusting maintenance schedules based on real-time equipment performance. Production managers aligning shift plans based on immediate material availability and order priorities. Executives making strategic decisions with a full understanding of operational challenges and capabilities.

This is the true power of alignment. Technology does not replace humans. It empowers them. Automation accelerates processes, but alignment ensures that those processes serve strategic goals and are adaptable to change.

Alignment is the Foundation for Industry 4.0 Success

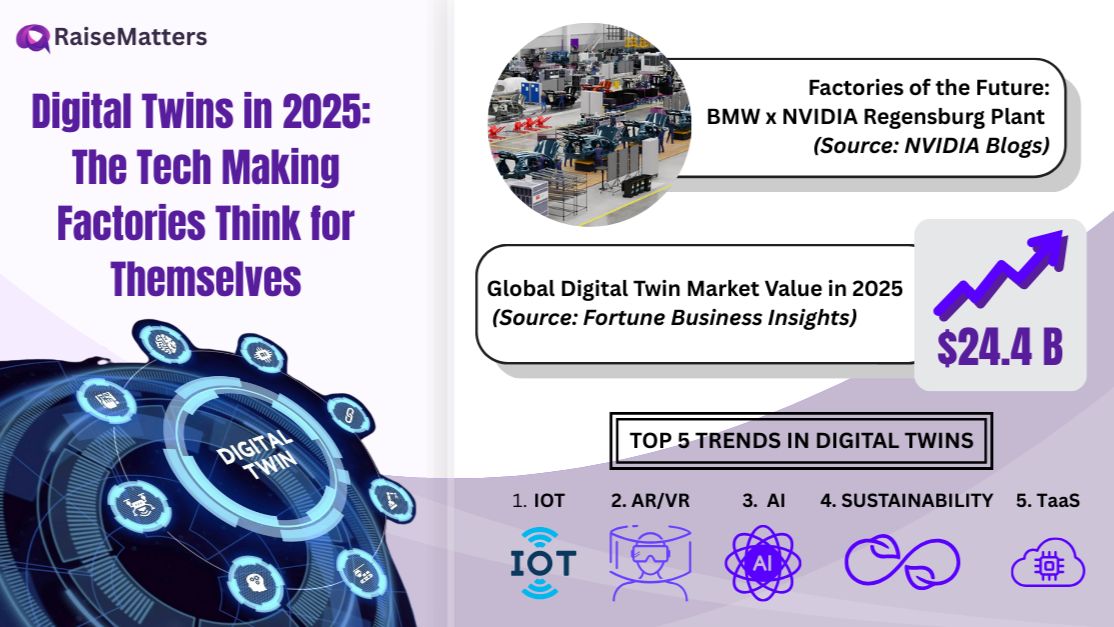

As factories move towards Industry 4.0, alignment becomes the critical foundation. Digital twins, MES, ERP integrations, AI-based predictive analytics, and cloud reporting platforms all promise transformation. But these tools only reach their full potential when they are implemented in a culture of alignment.

Factories that are aligned can adopt new technologies faster because teams are already working collaboratively with shared goals. They can derive insights from data faster because reporting structures are integrated. They can respond to market changes faster because leadership decisions are informed by ground-level realities.

Moving Beyond Metrics to Meaning

In the rush to modernise, it is tempting to measure success by how many machines are automated, how many sensors are installed, or how much data is collected each day. But these are surface metrics. The real question is deeper. How aligned is the factory? Are teams working towards common goals with clarity and confidence? Is data being used to drive meaningful action? Are decisions made collaboratively and with context?

Factories that lead do not focus only on automation targets. They build alignment as a strategic capability. This alignment allows them to integrate automation in ways that create systemic improvements, not just isolated efficiencies.

Automation may power the machines, but alignment is what drives progress. It is what transforms technology investments into business growth. It is what turns data into action, teams into collaborators, and factories into market leaders.

FAQs

What is factory alignment?

Factory alignment refers to the seamless integration of people, processes, and technology to ensure that operations, planning, reporting, and leadership all work cohesively towards shared goals. It turns data and automation into strategic advantages by connecting them to human decision-making.

How is alignment different from automation?

Automation uses technology to perform tasks without human intervention, making processes faster and more efficient. Alignment connects these automated processes with human expertise, strategic planning, and cross-functional collaboration to maximise value across the entire factory.

Why is alignment important in manufacturing?

Alignment reduces silos between departments, improves decision-making quality, and builds a culture of trust. It ensures that technology investments lead to real business outcomes such as higher productivity, better quality, and faster responsiveness to market changes.

Can a factory have automation without alignment?

Yes, many factories implement automation without alignment. However, in such cases, the benefits remain limited to isolated processes and fail to create systemic improvement across operations and strategy.

What are examples of tools that enable alignment?

Tools that enable alignment include Manufacturing Execution Systems (MES), ERP integrations, digital twins, and cloud-based reporting platforms. These tools provide real-time data visibility, connect operations with planning, and translate data into actionable insights for leadership and teams.

How can manufacturers improve alignment?

Manufacturers can improve alignment by:

- Ensuring data transparency across teams.

- Integrating operational data with planning and reporting tools.

- Training teams to interpret and use data for decision-making.

- Building a culture that values collaboration and open communication.

- Choosing technology solutions that enhance alignment, not just automate tasks.