Still, data on its own is not valuable. Without a way to capture, structure, and interpret it, even the most advanced systems can leave decision-makers in the dark. In a high-stakes manufacturing environment, relying on instinct alone is not just risky, it is inefficient. Your gut may be good, but your data is better.

Factories today are not short on information. What they often lack is visibility. The ability to know, in the moment, what is working, what is lagging, and where the next bottleneck might appear. Without clear measurement, teams are left reacting to symptoms instead of identifying root causes. And without standardised metrics, conversations about performance become fragmented, subjective, and slow.

This is why dashboards are not a luxury. They are a necessity. Dashboards translate factory activity into a shared source of truth. They make the invisible visible. Not as static reports that gather dust, but as living interfaces that guide decisions in real time. Measurement systems do not just monitor. They create accountability. When everyone sees the same data, progress is no longer about guesswork or individual heroics. It becomes structured, repeatable, and scalable.

Intelligent automation is not just about machines doing work—it's about reimagining how humans and technology collaborate to unlock new possibilities.

The key is not to measure everything. It is to measure what matters. A well-designed dashboard focuses attention on the critical few, not the trivial many. Output per hour. Downtime by cause. Quality deviations. Maintenance needs. Inventory alerts. These are not just numbers. They are early warnings, strategic levers, and growth signals. And when these metrics are visible to every layer of the organization, decision-making becomes democratic and responsive.

Some leaders hesitate to over-rely on measurement, fearing it will limit intuition or slow down operations. But good measurement does the opposite. It enhances judgment by adding context. It speeds up decisions by removing uncertainty. It gives operators, planners, and executives a unified language, so action happens with clarity instead of confusion.

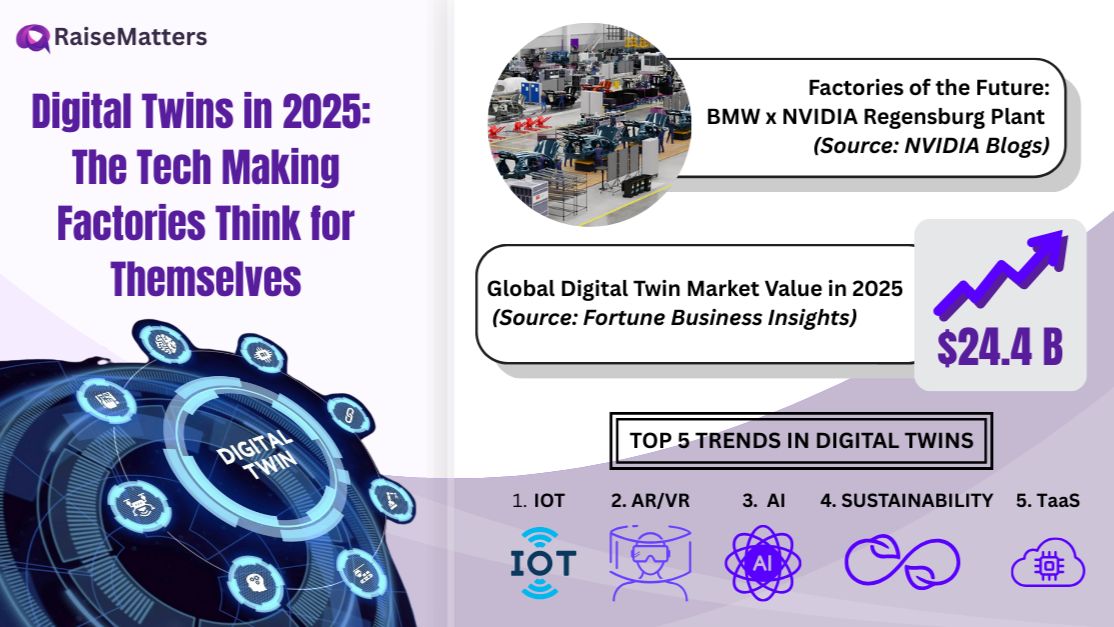

Measurement is also the foundation for automation. Machines can only be optimized if their performance is monitored. AI tools can only generate insights if the data is reliable. Predictive analytics only work when built on a history of consistent measurement. If your digital investments are not connected to clear, accurate metrics, they risk becoming sophisticated guesswork.

Measurement builds confidence. Not just in the systems, but in the people who run them. When everyone can track progress, identify issues, and contribute to improvements, a culture of continuous performance takes root.

In the modern factory, speed matters. Precision matters. But above all, clarity matters. And that starts with knowing exactly what to measure and how to use it.

Because in manufacturing, if it is not measured, it is just noise.

FAQs

Why is measurement critical in modern manufacturing?

Measurement turns operational data into actionable insights. It allows teams to track performance, spot problems early, and make informed, confident decisions at every level of the organization.

What is the difference between collecting data and measuring it?

Data collection is passive. Measurement is intentional. It involves identifying key indicators, setting benchmarks, and integrating them into daily decision-making processes.

What makes dashboards so essential?

Dashboards provide a real-time, shared view of factory health. They align teams around a common understanding and enable faster, more accurate responses to change.

How should manufacturers decide what to measure?

Start with your strategic goals. Identify the metrics that directly influence efficiency, quality, cost, and responsiveness. Focus on clarity, not volume.

What tools support better measurement in factories?

Manufacturing Execution Systems (MES), ERP platforms, digital twin software, and IoT-integrated dashboards all help structure and surface relevant performance data.

Can measurement replace human decision-making?

Not at all. Measurement supports better human decisions by reducing guesswork and grounding choices in real-time facts. It enhances judgment, not replaces it.